Products

Support

Contact Us

No. 509-510, Bldg B, Idea Industry Park, Fengxiang Road, Shunde District, Foshan, Guangdong, China

+86 186 8025 3077

+86 186 8025 3077

Mon - Fri (6:00 AM – 10:00 PM)

Sat - Sun (6:00 AM – 10:00 PM)

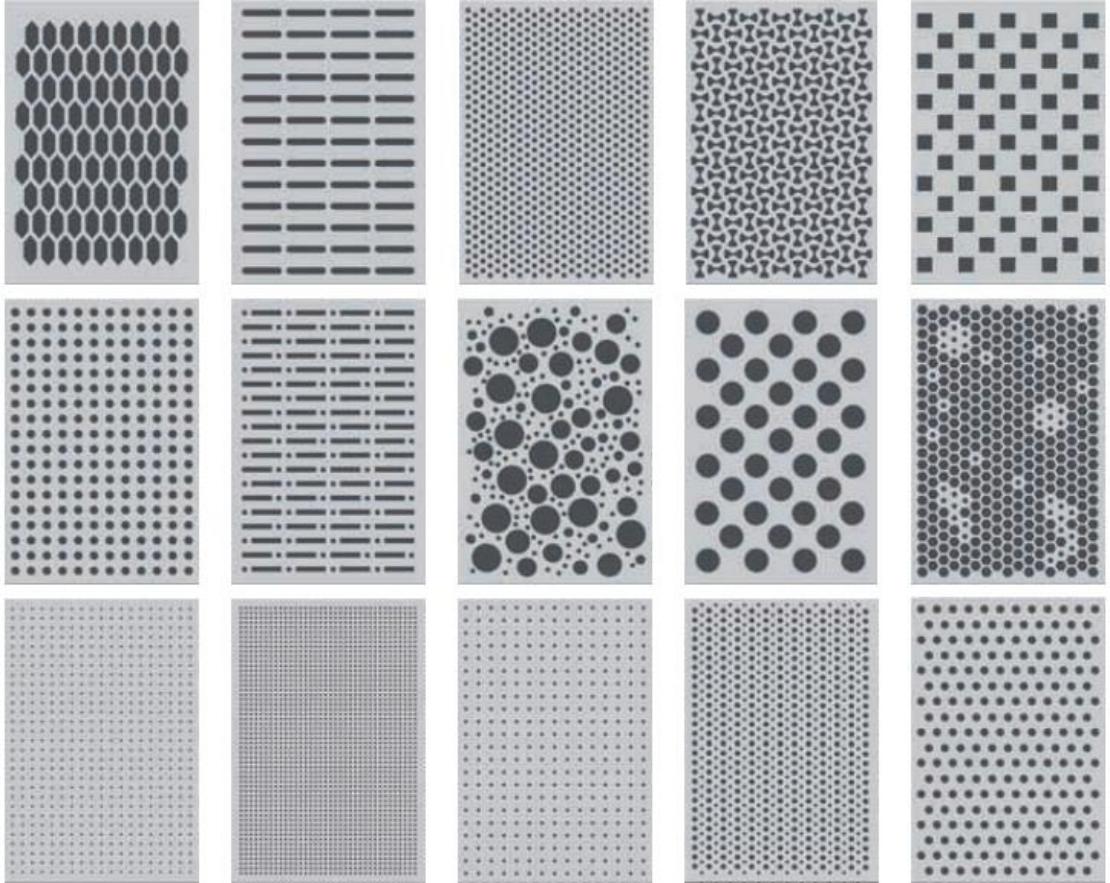

Punching aluminum panels in various sizes and designs are possible with CNC perforation technology. It may generate varied visual effects by using different punching patterns, and it is also effective for ventilation, heat transfer, light transmission, and sound absorption.

Read More| Material | Aluminum Alloy |

| Length | ≤6000mm |

| Width | ≤2000mm |

| Thickness | 1.0-4.0mm |

| Surface Treatment | PE, PVDF |

Puncturing aluminum paneling offers an efficient and straightforward approach to creating holes for fixtures or wiring, but it can also ruin the panel if care is not taken. Despite its malleability, aluminum is sought-after for many applications because of its lightweight, robust strength-to-weight ratio, and corrosion immunity. As a plus, its ductility makes forming and welding processes quite effortless and it features excellent electrical and thermal conductivity. This has made punching aluminum the go-to method for many contractors and homeowners looking to bring shapely and imaginative paneling into their homes.

| Product Type | Solid Aluminum Panel, Shaped plate (circular panel, double-arc panel, etc.),

Carved panels, large louver etc. |

| Certification | ISO9001:2000, CE, SGS. |

| Regular Thickness | 1.5mm, 2.0mm, 2.5mm, 3mm, 3.5mm, 4mm

Note: According to national Standards, the actual thickness is lee than the oretical thickness about 0.12-0.15mm |

| Max Size | 1500*4000mm |

| Raw Material | 1100, 3003 etc. |

|

Surface treatment |

Powder coated, PE, PVDF, Anodised, Woodgrain and Electrophoresis |

| Colour type | Solid colors, Metallic colors, Woodgrain, Marble and Rock color, etc. |

| Service | Manufacture products in accordance with customer drawings |

| Service Range | – Provide professional design and suggestion. – Purchase Raw materials and manufacture all kinds of products. |

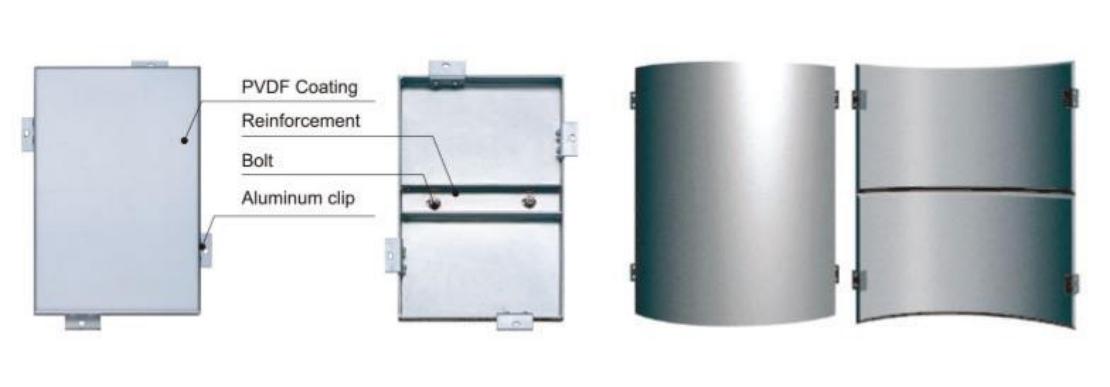

Aluminum curtain walls are constructed from high-strength aluminum alloy materials such as 1100H24 and 3003H24, with standard thicknesses of 2.0mm, 2.5mm, and 3.0mm. The standard maximum dimension is 1400 x 4000mm.

It is primarily constructed of an aluminum solid panel, reinforce rib, and angle clip. The reinforced rib strengthens the entire panel, ensuring panel flatness and shock resistance. Meanwhile, sound absorption and insulation materials can be mounted on the reverse of the panel.

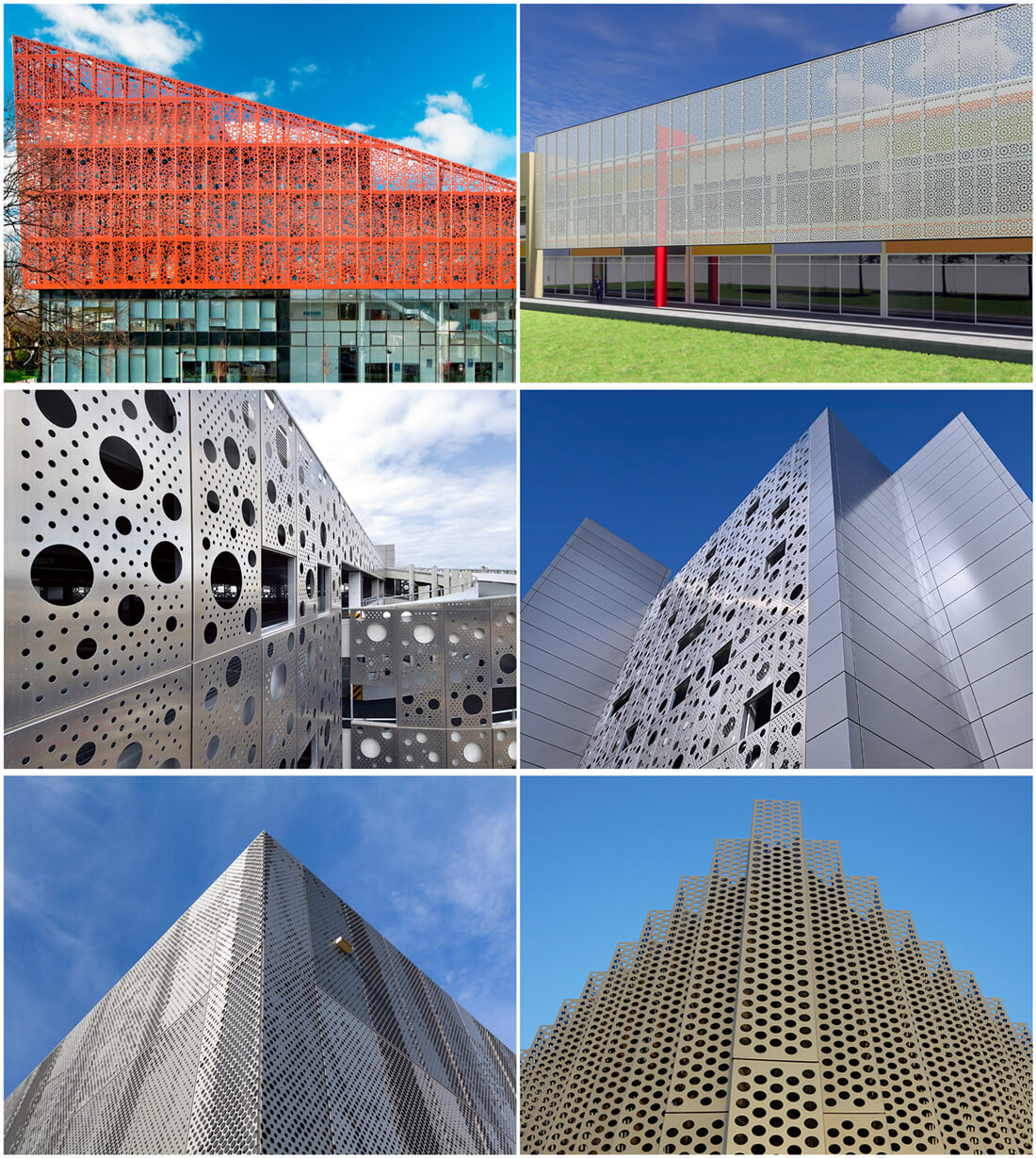

The punched aluminum veneer is a type of aluminum veneer that is produced by punching a design into a sheet of aluminum. This type of veneer is often used for decoration or to add a visual element to a surface. The punched aluminum veneer can be used on both indoor and outdoor surfaces.

Punched aluminum panels are an aesthetically appealing and customizable solution to spruce up any space. Whether for indoor or outdoor residential or commercial use, these panels are available in a rich spectrum of colors, patterns, and finishes. In terms of architecture, punched aluminum panels can serve as a statement-making façade or accent wall for a variety of projects. Additionally, they offer a clean-cut appearance that can complement and elevate the look of any design.

Customized Decorative Panel Experience

Customized Decorative Panel ExperienceWith so many people now working from home, the demand for customized decorative panels has sky-rocketed. Customized perforations, customized sizing, and careful attention to your needs ensure that you obtain the exact product required to complete your project. Our panels are made of MDF and can be used for a variety of purposes, such as wall art, room dividers, or even furniture.

No. 509-510, Bldg B, Idea Industry Park, Fengxiang Road, Shunde District, Foshan, Guangdong, China