Country: Philippines

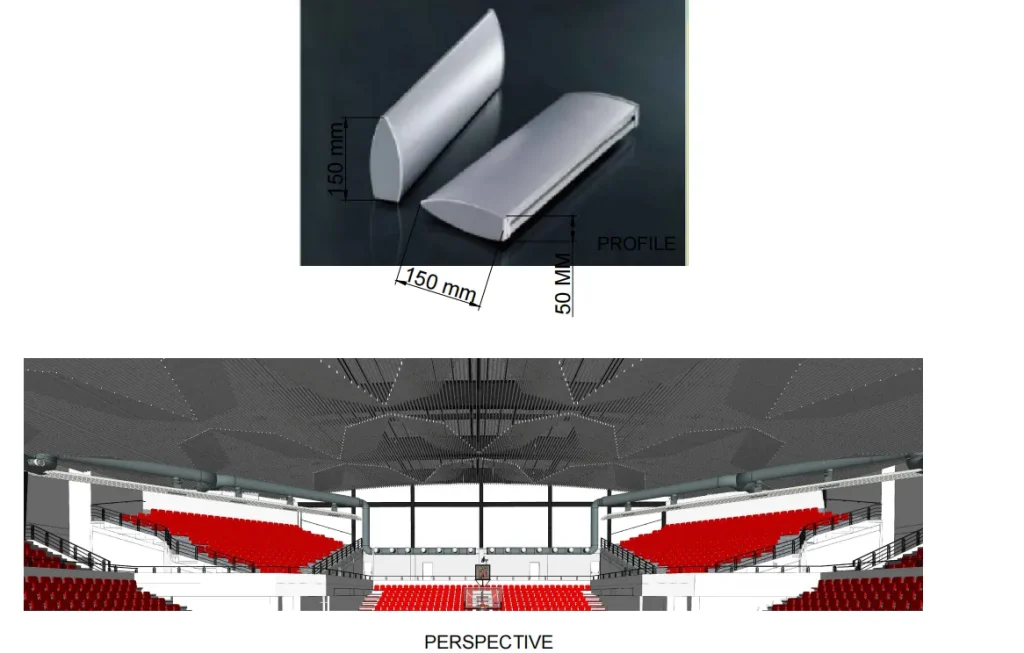

Products: aluminum profile square tubes

Project: Aluminum profile square tubes for a Philippines Tarlac City Gymnatorium

1. Receved project information from client:

At the beginning, the client don’t have specific designs on the project. So we share our catalog with designs and clients for client’s reference and choice. Finally, the client share the design they chose and have deep discussion on the product details to confirm.

2. Solutions provided:

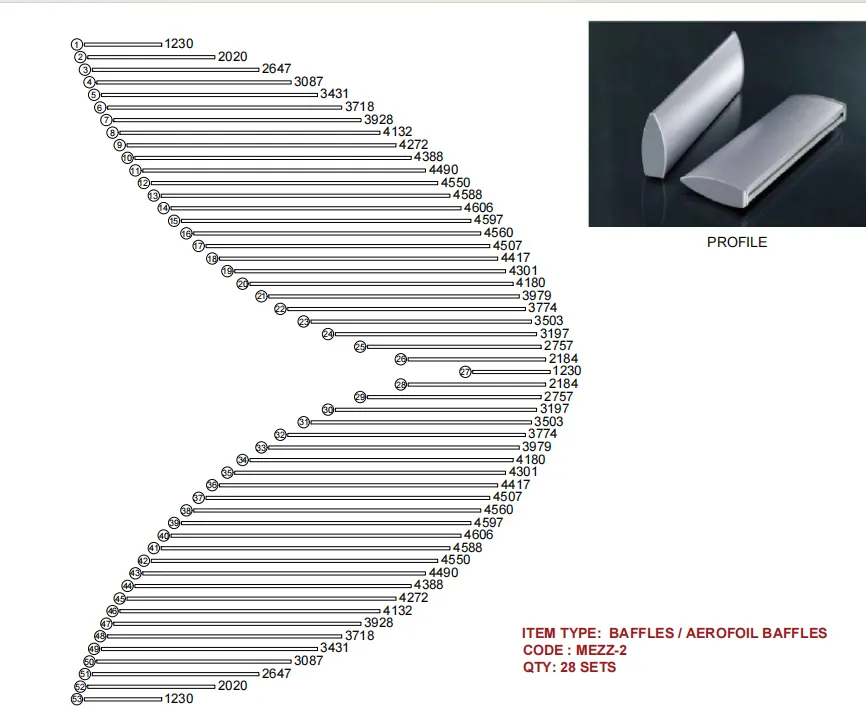

- Length coordination: Since the client required panels of different shapes, the project involved multiple length specifications. Through close communication and coordination, we finalized an optimized length plan that met the design requirements while ensuring smooth installation and structural stability.

- Color optimization: The client initially preferred a wood grain finish; however, considering the higher cost of wood grain coating, we recommended using a brown color that closely matched the wood tone. This solution achieved a similar aesthetic effect while significantly reducing procurement costs, balancing both visual appeal and cost efficiency.

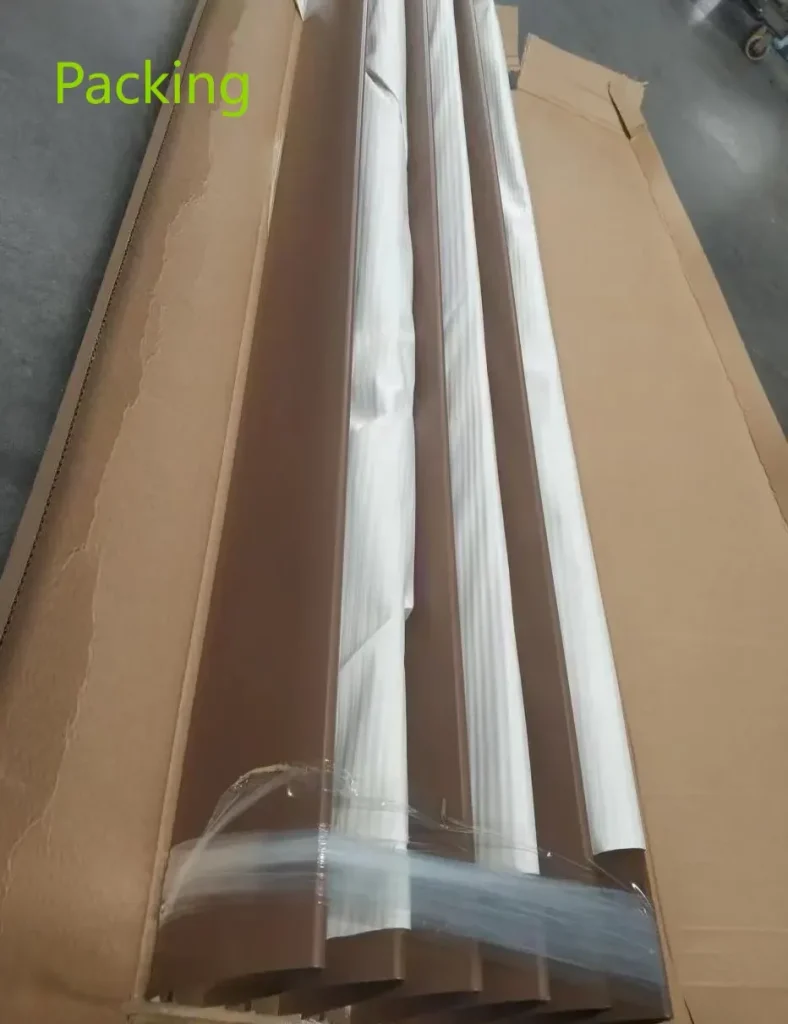

3. Start production after shop drawing confirmed:

Once the client has confirmed the solution and drawings, we will proceed with production, and share production photos with client for them to clear about the process and rest assured.

4. Completed installation photos:

After the installation was completed, the client was very satisfied with both the overall effect and the stability.